Processes4AM

WIRE ARC Additive Manufacturing (WAAM)

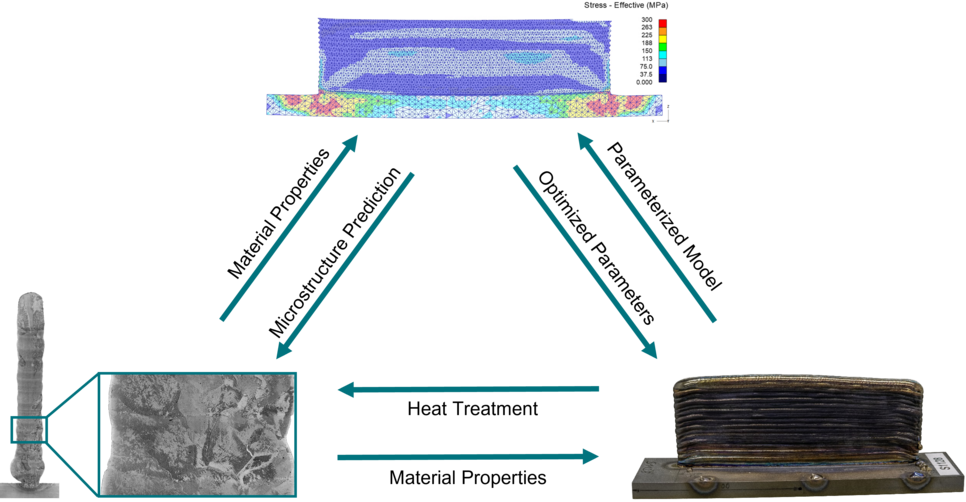

Especially for large components, processes like WAAM are applicable to cut on production cost and time. The use of CMT welding technology enables deposition rates of up to 5 kg/h in form of a molting wire electrode. Combined with a 6-axis industrial welding robot, a very flexible and universal manufacturing call can be established. However, the large number of process parameters and influencing variables make it difficult to achieve a stable process and produce reliable predictions trough simulation. Therefore, project “CyberWire” was created to build machine learning supported parameter optimization strategies. By the gradual convergence of the process and numerical simulations like FEA and CFD, a digital shadow shall be built. A combination of black-box models and physical interpretations, so called grey-box models, can be formed to enhance process understanding, especially in areas hardly observable in-situ like microstructure evolvement and residual stress build up.

Current studies include:

- Improvement of welding parameters to optimize the as-built microstructure of Ti-6Al-4V and the introduction of additional control features with ultrasonic transducers

- Improvement of movement parameters and path planning strategies to optimize geometrical features and prevent voids in dense areas

- Coupling of the production cell and the Finite-Element process analysis

- Digitalization and retrofitting of additional measurement devices

For question please contact Chair of Metal Forming

Publication:

Thermo mechanical Finite Element Analysis of the plasma Wire Arc Additive Manufacturing process in DEFORM® 13,

Journal of Advanced Joining Processes, Volume 12, 2025, 100321, ISSN 2666-3309,

doi.org/10.1016/j.jajp.2025.100321.

Metal Alloy Powder Production

The Chair of Material Physics has infrastructure to produce individual metal powders for additive manufacturing. The powders have a rapid solidified microstructure and have an adequate powder size to be used in metal laser or electron beam powder bed process. Please contact the chair for further information and research opportunities.

Beam Powder Bed Processs

The Montanuniversitaet has a focus on the research in laser or electron beam powder bed processes. Studies help to develop the right processing parameter for reaching dense, defect free parts. Heating platforms adjust a controlled heating cycle of the parts. The usage of protection gas or vacuum environments prevent oxidation. Please contact for further question and research opportunities the following chairs:

Laser beam powder bed:

AM Extrusion and Filament Production processes

The AM Filament Extrusion offers a wide range of parts and materials. The Chair of Polymer Processing has the expertise and the experimental infrastructure to provide small (100g) to bigger batches (20kg) batches of pure polymer or composite filament batches. Various 3D printing system offer to study the influence of the production parameters on the properties of the 3D printed parts. The research group has many experience in national and international funded research projects. So if you have further question or you are interested in research collaboration contact either Department of Industrial Liaison or the Chair of Polymer Processing directly. In cooperation with the other chairs of the Department of Polymer Engineering access to various characterisation methods and mechanical testing is given.

Material Jetting

The Department of Polymer Engineering offers research options of 3D jetting of polymers. Two different production methodologies and equipment types are available.

- The Freeformer - contact Chair for Polymer Processing

- 3D Printing - contact the Chair for Chemistry of Polymeric Materials

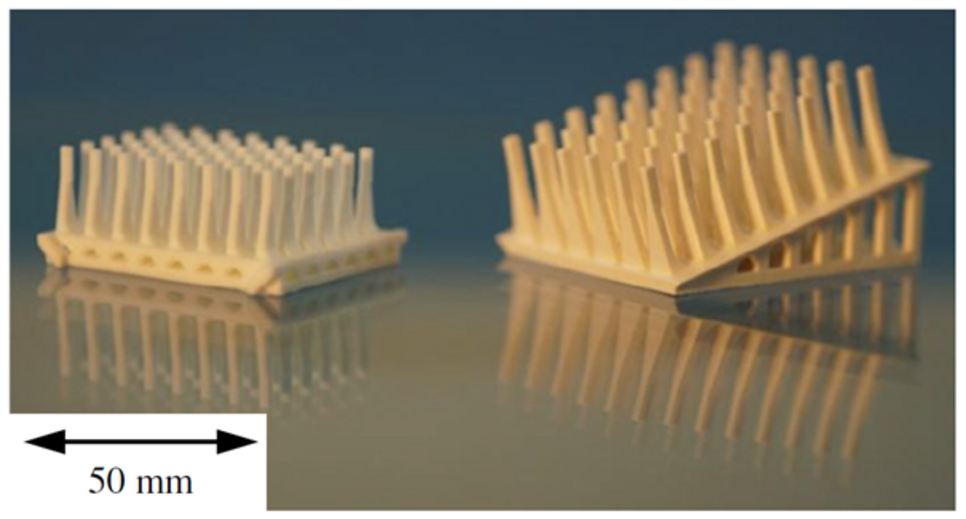

Stereolithographic Processes

In Stereolithographic Process the Montanuniversitaet has a wide range of activities. For the 3D ceramic parts Lithoz devices are in use. In polymer resins printing the materials development is coupled to the development of individual machines to reach the optimum properties of the novel polymeric materials. If you have any further question or interested in research cooperation please contact

- Ceramic materials: Chair of Structural and Functionals Ceramics - Printing of Mulitlayered Ceramics, specific test specimen shape geometry

- Polymeric Resins: Chair of Chemistry of Polymeric Materials