Characterisation 4 AM

Microstructure and Defects, Properties of AM Materials and Parts

In materials development the materials properties are always correlated with process and process parameters by the microstructure – property correlation. Additive manufacturing shows other process characteristics, so the understanding of the formation of microstructure, defect structure, stresses or orientation effect are important to understand the behaviour of the AM fabricated materials and parts.

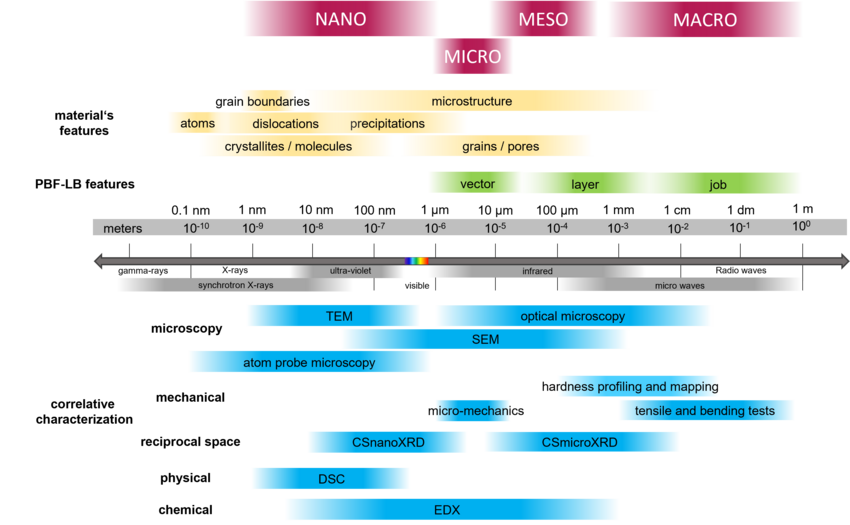

Many additively manufactured materials exhibit an outstanding performance compared to their conventionally produced counterparts. Reasons behind can be determined by a multi-scale characterization approach combining results of several different methods.

Characterization possibilities for additively manufactured components at MUL encompass all kinds of microscopy (transmission electron microscopy TEM, scanning electron microscopy SEM, optical microscopy), mechanical (tensile and bending tests, fatigue tests, etc.), physical (differential scanning calorimetry DSC) and chemical analysis (energy dispersive X-ray spectroscopy EDX, mass spectrometry) and characterization methods deploying the reciprocal space (X-ray diffraction).

Scientists from different institutes and chairs of the MUL work together in order to contribute with their expertise to the characterisation of AM components on different length scales. The approach to the investigation is adapted and developed material- and process-specific in order to be able to define an effective investigation standard. The collaboration with MUL ensures that phenomena in AM samples from newly developed material systems are also efficiently investigated and subsequently understood - regardless of whether inorganic materials such as ceramics and metals or organic materials such as polymers or various binder systems are involved.